Cable Duct Mould Wpc Extrusion Moulding 3cr13 3cr17 Garden Outdoor Pillar

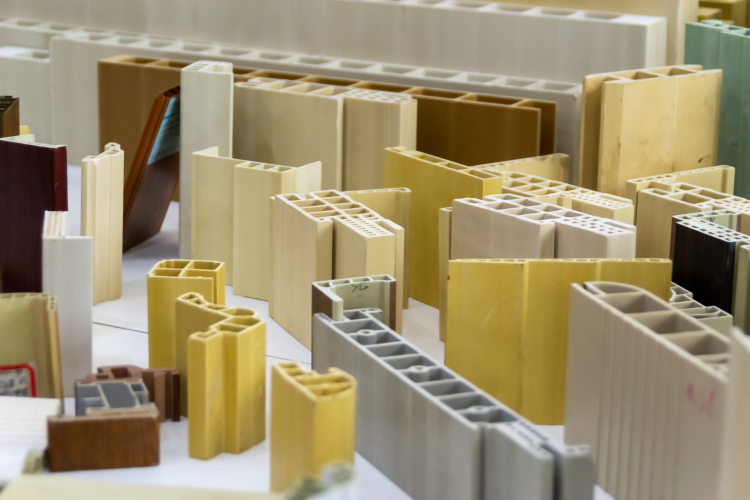

This company produces the PVC Extrusion Moulding、WPC door fram mold、WPC Fram Door Mould、WPC Mould、PVC Windows mould、PVC Fram Door Mould、PVC Extrusion Mould、PE Wood Decking mould、PE wood mould

Technical advantages:

1.Adjust the mold parameters according to the composition of the material formula

2.the mandrel for special treatment and wear resistance and corrosion resistance, long service life

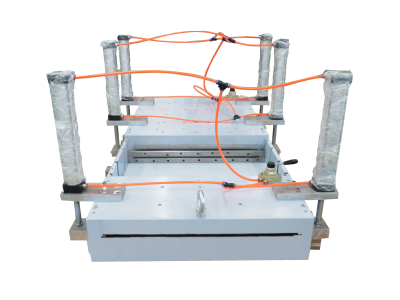

3.Advanced cooling system design, good cooling effect and convenient cleaning

4.according to the customer's raw materials, design experience value is unique to each

5.The mold cavity parameters and water and gas discharge are reasonable, and the extruder can play a better production capacity

Mould Name | PVC Foaming Mould |

Mould cavity | 1 or multi-cavity |

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Features | Selectable co-extrusion of different raw materials: PVC/WPC/UPVC/PE/PP/PS/ABS |

Selectable technology | low-foaming, high-foaming & substance co-extrusion |

Stable | discharging, high efficiency, superior quality |

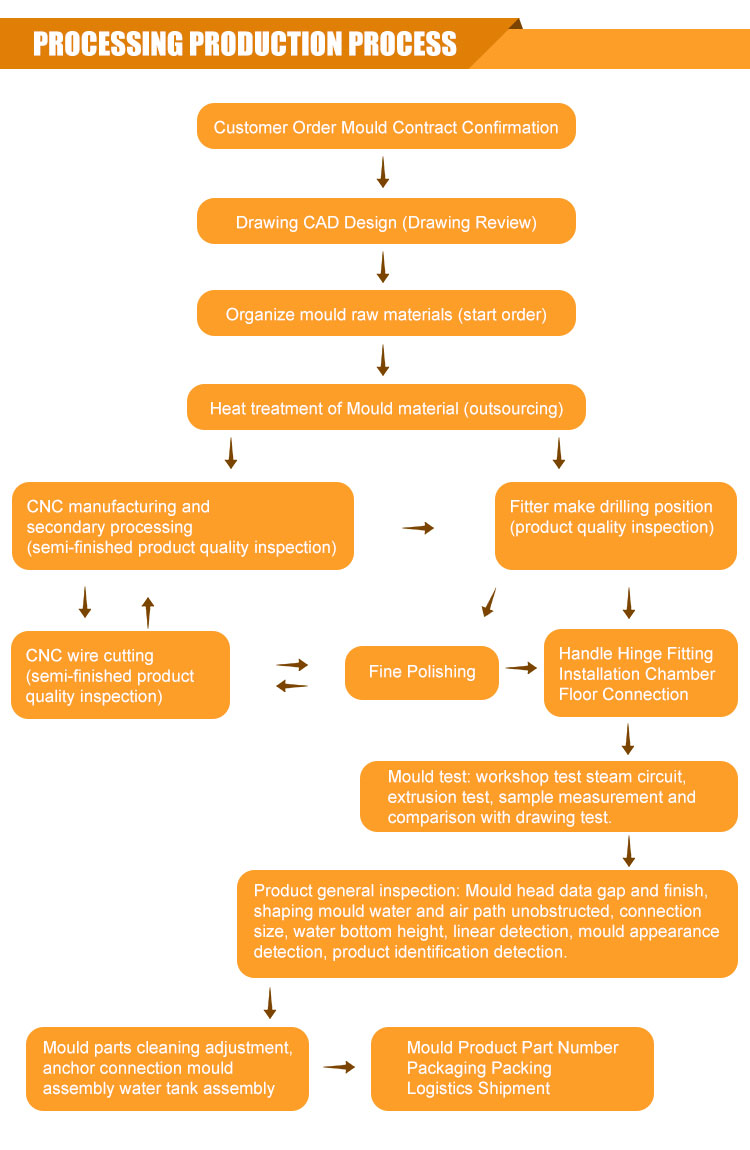

Test | Mould will be tested to get the satisfied sample before delivery Service |

Lead time | 30-40 days |

Application | Architecture decorative panel; wall panel;Shutter; landscape construction |

Characteristics of wood plastic foam products | Wood-plastic foam products are widely used in indoor and outdoor decoration, environmentally friendly interior decorative lines, foam boards, cabinet boards,wood-plastic profile furniture materials,homes,engineering,office buildings, hotels, restaurants, entertainment venues, etc., and can be substituted Traditional decoration materials such as wall paint and wallpaper are easy to disassemble and save time and effort. It has the characteristics of environmental protection, moisture proof, heat preservation, sound insulation, fire prevention and convenient cleaning. |

Extrusion mould material | 3Cr13,3Cr17,D1.2316 stainless steel |

Size | Various types |

A: In general, it will take 4-5 weeks, depending on the complexity and cavity Number of the mold.

Q2: What type of CAD files do you accept?

A: We are able to accept DWG,DXF files. If you would like to send us your file via email attachment, please send it to sales03@alpinemold.com.

Q3: How do you provide after-sales service?

A:We provide after-sales service within one years after customer receive the mold. If the service area is in civil china, the cost is free.

Q4: Do you provide product assembly service?

A: we can provide production run and assembly service.

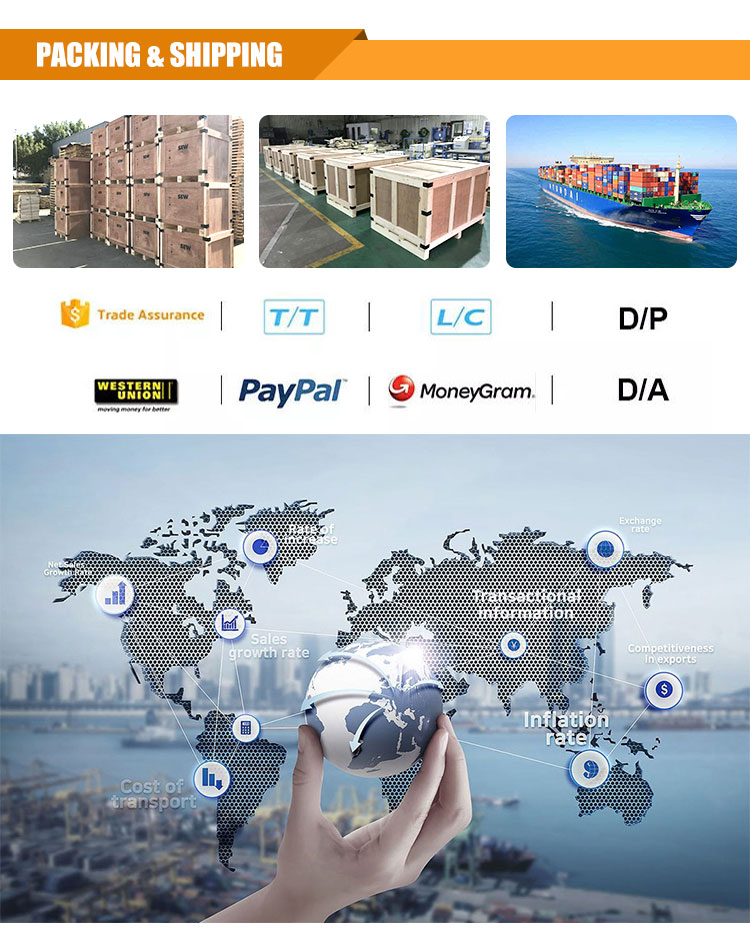

Q5: What is your payment term?

A: T/T is workable to you, normal we accept T/T Min 30% with order, and the balance before the shipment.

Q6:What is your business scope?

A:Our business scope is plastic mould,plastic extrusion product,plastic machine,etc, we can provide one-stop service.

Q7: How can I know the completion of my order?

A: Upon receipt of the deposit, we will immediately arrange for the production, after the order is completed, we will inspect and test all products carefully to ensure no damage and lost, we will also send you the detection images of your order before delivery for you,etc.

Q8: Can you guarantee your products?

A: Yes, base on our order and contract detail,we guarantee your 100% satisfaction on all our products.

We are a manufacturer with more than 20 years experience,our professional team will provide you with the right solution and high quality products....more