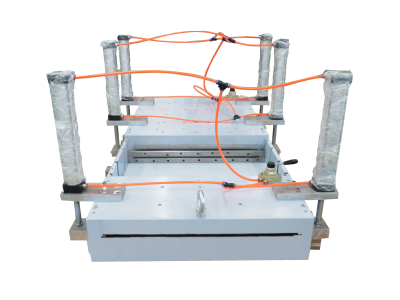

Wpc Sheet Head Pvc Stone Lamination Panel Mold Die Extrusion Mould

Brand:

DAYUANmold

Product origin:

china

Delivery time:

35day

Supply capacity:

20

Wpc Sheet Head Pvc Stone Lamination Panel Mold Die Extrusion Mould

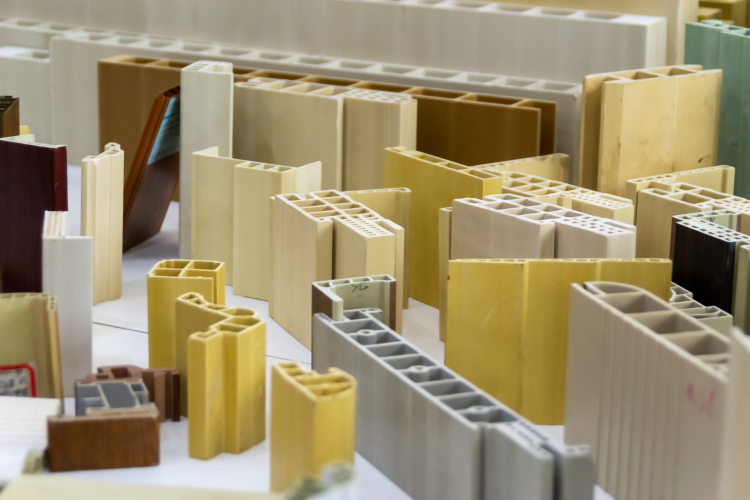

This company produces the PVC Extrusion Moulding、WPC door fram mold、WPC Fram Door Mould、WPC Mould、PVC Windows mould、PVC Fram Door Mould、PVC Extrusion Mould

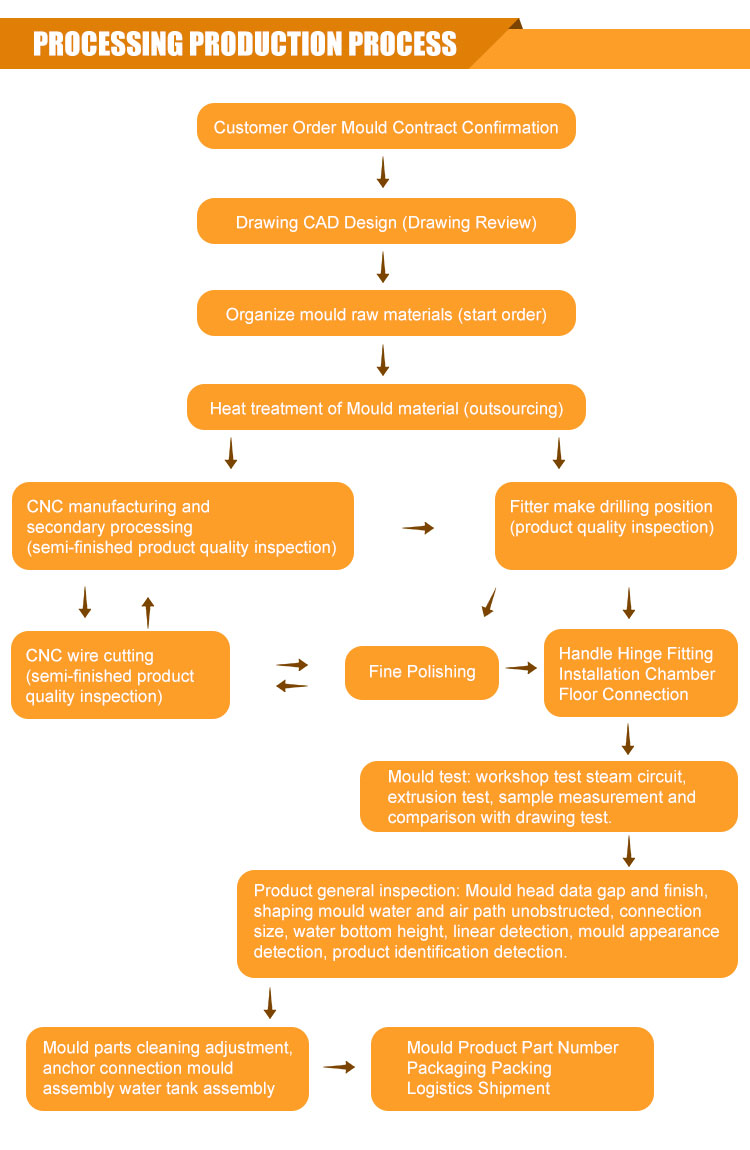

Technical advantages:

1.Adjust the mold parameters according to the composition of the material formula

2.the mandrel for special treatment and wear resistance and corrosion resistance, long service life

3.Advanced cooling system design, good cooling effect and convenient cleaning

4.according to the customer's raw materials, design experience value is unique to each

5.The mold cavity parameters and water and gas discharge are reasonable, and the extruder can play a better production capacity

Are you a trading company or a manufacturer?

We are a manufacturer with more than 20 years experience,our professional team will provide you with the right solution and high quality products....more

We are a manufacturer with more than 20 years experience,our professional team will provide you with the right solution and high quality products....more